AI Boosts Tampa Bay Microbrewery Consistency & Quality

How Tampa Bay Area Microbreweries Can Leverage AI for Superior Water Quality and Flavor Consistency

Anheuser-Busch InBev’s AI Implementation Case Study

Anheuser-Busch InBev (AB InBev), the world’s largest brewer, has already shown the beer world what happens when algorithms meet barley. This global powerhouse treats artificial intelligence not as a shiny gadget but as a hardworking partner woven into daily brewing routines. By handing repetitive, data-heavy tasks to machine-learning models, AB InBev has dramatically upgraded its beer filtration process, tightened quality control, and shaved meaningful dollars off operating costs.

The headline stat is hard to ignore: the company’s “Planning in a Box” initiative drove a 60 percent leap in efficiency for every brewing run. Think about what that actually means on the floor. Fewer stoppages. Fewer last-minute ingredient scrambles. Fewer “Is this batch going to taste like the last one?” conversations. AI pores over historical batch data, forecasts demand, and optimizes production schedules, freeing human brewers to focus on creativity and taste rather than spreadsheets.

Most important, the beer itself benefits. Consistency—often the Achilles’ heel of craft operations—has tightened to near-industrial levels, even while flavor profiles stay true to brand. In other words, the algorithm handles the drudgery of monitoring variables such as temperature curves, pH drift, and filter life. Brewers can then spend their energy refining hop schedules or experimenting with that rye-whiskey barrel aging project they’ve been itching to try. The lesson is straightforward: if a multinational like AB InBev can plug AI into an operation that spans continents, the underlying concepts are absolutely within reach for a nimble microbrewery right here in Tampa Bay.

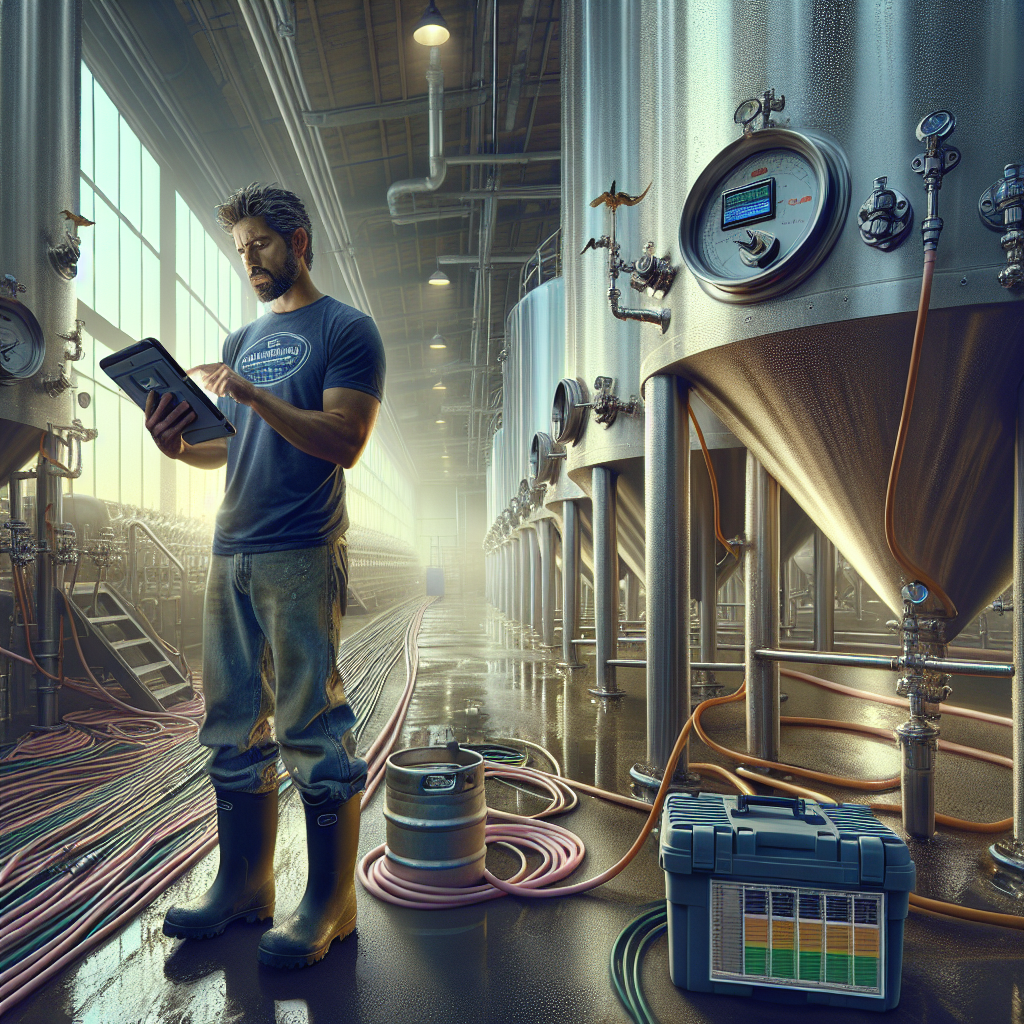

A Hypothetical Scenario for a Tampa Bay Business

Now, picture Cigar City Brewing—or any local brewery tucked between the bay and the Gulf—deciding to borrow a page from AB InBev’s playbook. How might that look in practice? Below are two concrete, only-half-imaginary applications that could be rolled out without turning your brewhouse into a sci-fi lab.

-

Enhanced Water Quality Monitoring: AI-driven sensors, installed inline, could check mineral composition and pH in real time as municipal water flows into your hot liquor tank. The system instantly tweaks calcium or bicarbonate additions to lock you into the sweet spot for each recipe—no need to wait for a lab test or taste-panel feedback. Consistent water chemistry means the malt pops the same way in January as it does in August, even when Tampa’s water profile changes after a storm.

-

Optimization of Brewing Conditions: Historical batch logs—temperature spikes, gravity readings, fermentation times—feed into a machine-learning model that identifies the goldilocks zone for every yeast strain you use. The software flags fermentation outliers before they create off-flavors, and it recommends subtle mash-temperature adjustments when it detects a drift in extract efficiency. Fewer dumped batches. Fewer surprise diacetyl bombs. More reliable IPAs flying out of the taproom.

Why This Matters to a Microbrewery’s Daily Grind

AI doesn’t replace your head brewer’s palate or creativity. What it does, however, is shoulder the monotonous vigilance required for top-tier consistency. That vigilance grows in complexity as a brewery scales from “friends-and-family garage setup” to 20-barrel production runs supplying bars from Ybor City to St. Pete Beach. Handing that chore to a system that never sleeps or looks at the wrong line on a spreadsheet is a competitive edge hiding in plain sight.

Think of it this way: Tampa Bay drinkers love variety, but they also expect Jai Alai to taste like Jai Alai every single time. An AI guardrail around water chemistry and fermentation data means your brewers can riff on seasonal one-offs—key-lime wheat, Cuban-espresso porter, mango gose—without the nagging fear that core brands will suffer. That separation of “core-brand consistency” and “taproom experimentation” is the dream many local breweries chase, and AI helps make it reality by reducing the risk side of the equation.

Dollars, Sense, and Practical Roll-Out

“Yes, but at what cost?” Fair question. While AB InBev’s budget is in a different stratosphere, microbreweries don’t need enterprise-grade servers in a climate-controlled data center. Many sensor packages and cloud-based analytics tools operate on subscription models. You pay monthly for the data crunching, the same way you pay for your point-of-sale or accounting software.

Start small. Maybe you begin by integrating smart pH and conductivity probes tied to a dashboard accessible on a tablet. The brewery collects a few months of baseline data so the algorithm can learn. Once trends become clear, you add a predictive module that suggests lactic-acid additions or mineral tweaks before issues arise. Next, you feed in fermentation logs from your existing brewery management software. The system flags any red flags—rapid attenuation, stuck fermentation—while the beer is still salvageable, not once it’s in the drain.

Local equipment suppliers have already caught wind of this demand and can integrate sensors during a brewhouse upgrade or glycol system overhaul. Pair that with Tampa Bay’s growing community of tech consultants who understand both data science and beer, and the barrier to entry drops even further.

Culture and Team Buy-In

Technology alone won’t carry the day. The brewers, cellar operators, and even taproom teams need to see AI as an assistant, not a replacement. Educate staff on what the system measures, why it matters, and how it can help them dodge problems before they become crises. Early wins—saving a batch that looked doomed or nailing water chemistry on a new recipe—build trust and enthusiasm.

You also preserve the artisanal soul of brewing. The algorithm does the math; the brewer still chooses the hop blend that will wow tourists on the Riverwalk. In fact, with the stress of constant data checks lifted, creative energy often spikes. Several craft breweries that experimented with AI in pilot form found that recipe development meetings became more ambitious because the team felt confident the fundamentals were locked down.

Long-Term Strategic Upsides

-

Brand Reputation: Consistent flagship beers secure tap handles in competitive bars and restaurants from Channelside to Clearwater. Distributors notice fewer returns, and your brand reputation solidifies as “the craft brewery that always nails its profiles.”

-

Regulatory Assurance: The same sensors that track pH and turbidity can automatically generate compliance reports for local water authorities, saving admin time and avoiding fines.

-

Sustainability Wins: AI-guided filtration and heating cycles use less water and energy. Less waste is good for the planet and great for your utility bills.

-

Data-Driven Growth: Once you’re capturing high-quality production data, you can start aligning it with sales trends. Suddenly you’re not just guessing which seasonal beer to double next year—you’ll have predictive models showing demand curves and margin projections.

Wrapping It Up

AB InBev’s success with “Planning in a Box” proves that AI can tame the complexity of modern brewing without flattening its artistry. Tampa Bay’s microbreweries occupy a sweet spot: small enough to pivot quickly, yet big enough that consistency challenges are real and costly. By weaving in AI—first for water-quality oversight, then for deeper fermentation and scheduling insights—you protect the taste patrons love while freeing human talent to push boundaries.

The tools are no longer reserved for corporate giants. Cloud subscriptions, drop-in sensors, and local tech talent make AI approachable and affordable. Brewers can spend more time dreaming up grapefruit-infused pale ales inspired by the Sunshine Skyway and less time babysitting spreadsheets.

Blend age-old craft with twenty-first-century smarts, and Tampa Bay’s beer scene could set a new standard others rush to follow—proof that even in a region already bursting with flavor, there’s always room for a little extra intelligence.

Case Study Source

Anheuser-Busch Inbev: Case Study: AB InBev Integrates AI for Innovation and Efficiency - AIX - AI Expert Network

Next Step

Ready to unlock the power of AI for your business? Contact EarlyBird AI today for a free consultation and discover how our tailored solutions can drive growth and efficiency for your Tampa Bay enterprise.